From time to time new technologies appear that revolutionise the world. Whether it was the light bulb, iPhone, computer or solar cell, they were all met with scepticism and the feeling that it was ‘too good to be true’.

What follows is an introduction to such a new disruptive technology, which is finally being commercialised after years of research and development, proving in laboratories and critically, assessment in real-world operations.

The economic value of the technology is so great that a fully integrated solution can be provided, for approved installations, at no capital cost.

‘Too good to be true?’ At first glance yes, but FUELSAVE, the technology supplier, will supply, install and maintain their solution*, at their own capital cost, with no lease or other payments from you. Their income, which funds the equipment, is derived solely from their share of the fuel cost savings.

Your substantial share of the fuel cost savings will go to your bottom line and provide a welcome cash injection to fund capital works, such as the transition to renewable energy.

The substantial reduction in emissions and operations costs are a bonus to help you to immediately meet regulatory and community expectations.

Technology Overview

Hydrogen is the fuel of the future! If the composition, admixture and dosing is right, Hydrogen significantly increases the combustion efficiency of today’s engines, especially when using liquid fuels, like Diesel or Heavy Fuel Oil. FS even improves efficiency of gas (LPG, CNG) engines.

———-

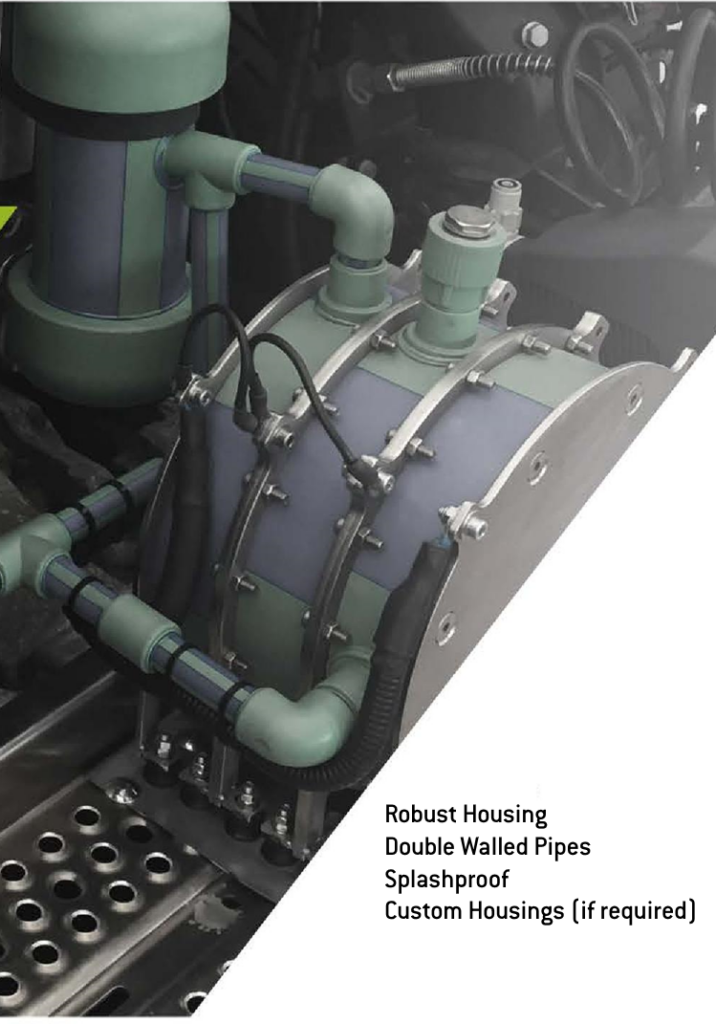

FUELSAVE’s patented combustion conditioning technology uses dynamic & load based injection into several place in the air intake.

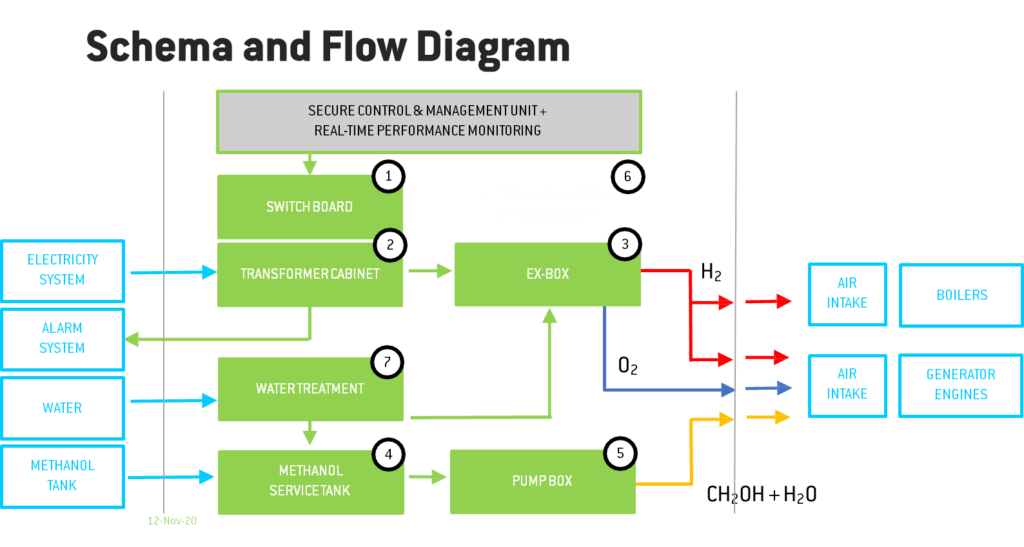

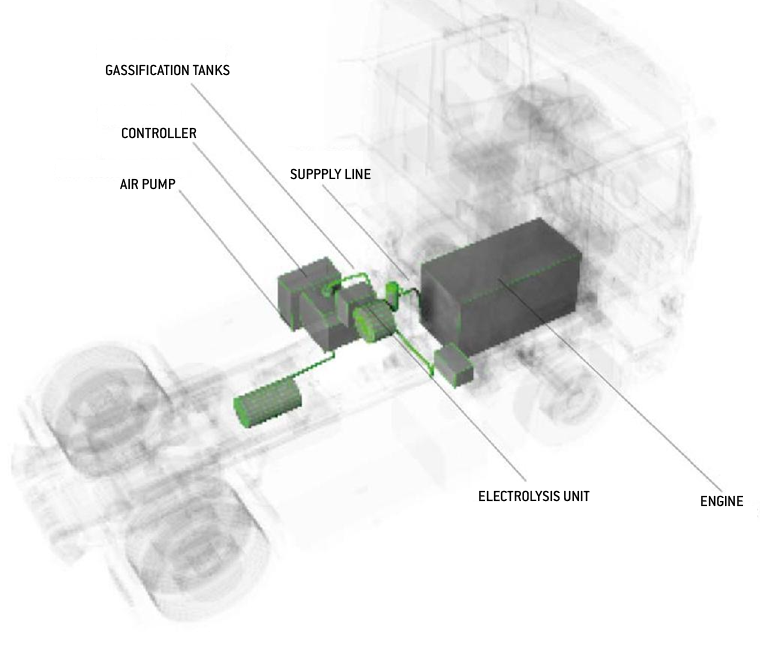

We produce, mix and inject:

- An FS electrolysis unit splits purified water into hydrogen & oxygen gasses. (The hydrogen is produced on-demand and is not stored.)

- In a second FS tank, alcohol (methanol/ethanol) is stored and volatalised on-demand.

- A FS high-performance pump injects the synth gas into the engine’s turbocharger which forces the air/synth gas mixture into the combustion chamber as in normal engine operations.

- A second FS air pump increases on-demand production of the synth gas.

Working Principles

Optimisation of the stoichiometric fuel mix, based on the specific engine combustion chamber geometry and related turbulence and load.

The most appropriate combination of hydrogen, oxygen, methanol and water is injected into 3 different locations of the air intake which impacts:

The gaseous injection helps more thorough fuel combustion by leveraging the steam effect of the water and a boost from the methanol.

The fuel governor and engine management system detects that pressure is sufficient and throttles down the primary fuel to keep the kW output constant.

Implementation Overview

FUELSAVE is designed to be retrofitted:

We secure technical signoff from your engine manufacturer and support engineers.

Quick and reversible integration via air intake of existing plant (less than 24 hours downtime)

- Components installed by technicians approved by you, under expert direction of and paid for by FuelSave

- No need to touch software, fuel supply systems or cylinders

- No impact on generator up time.

- If there is a FUELSAVE system’s issue, generators operate as if the FUELSAVE system had not been installed ie operates as per normal.

If FS system fails to perform as guaranteed, it can be removed within 14 days.

After the technical sign off from your engine manufacturer and engineering firm, we can determine which is the most effective method for implementing our solution to meet your site constraints.

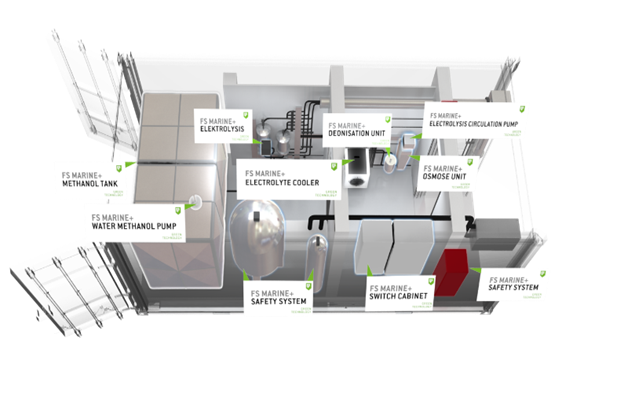

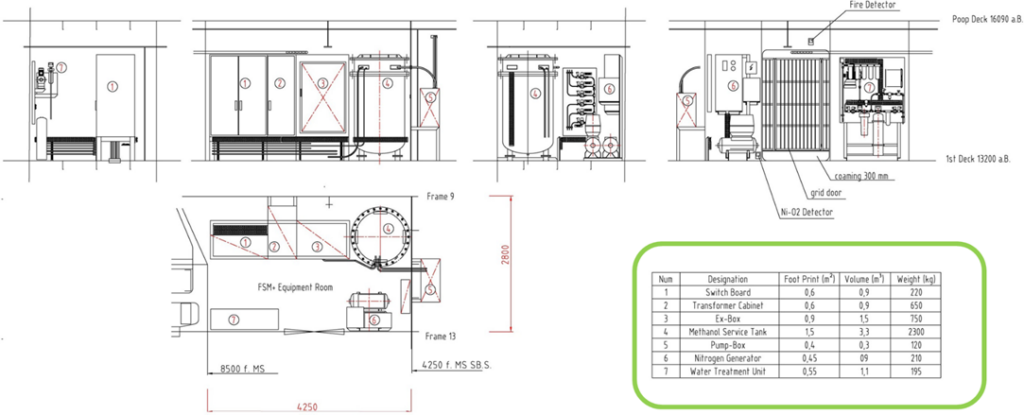

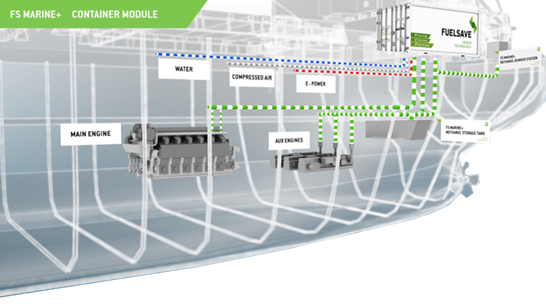

Containerised Solution

CONTAINERISED SOLUTION (+/- 4 months lead time)

- AIO solution

- Reusable from one asset to another

- Minimum site preparation costs

- Hot swappable for maintenance ´

Integrated Solution

Where space is available, components are located within plant buildings.

Typical vehicle installation.

Proven Performance

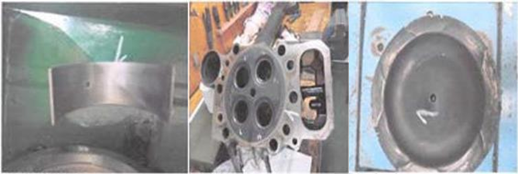

CBH is one of the most respected engine service specialist companies in Germany. They are the long term engine service company for SAL. They conducted the 1,000 hour inspection on the SAL Heavy Lift Vessel, MV Annette.

“It is a matter of fact, we have been maintaining the … aux engines for some years. They run on MDO, have always been well maintained and operated under normal conditions, but since we installed the FUELSAVE SYSTEM, the engine has become much cleaner. There is no visible soot and the engine running is much smoother, with reduced levels of noise and vibration. The improvement is astonishing. This is something very special.” CBH MANAGING DIRECTOR CARSTEN KÖRBELIN

DNVGL is a global leader in engines.

They conducted the 5,000 hour inspection of th eengines and the FUELSAVE system

CONCLUSIONS

- No problems detected

- 100% positive report

- Engine dismantled

- no negative finding

- images illustrate reduction in carbon build up

- FS Marine Unit

- 100% satisfactory result

- * the no capex solution is subject to an evaluation of your requirements. See our disclaimer